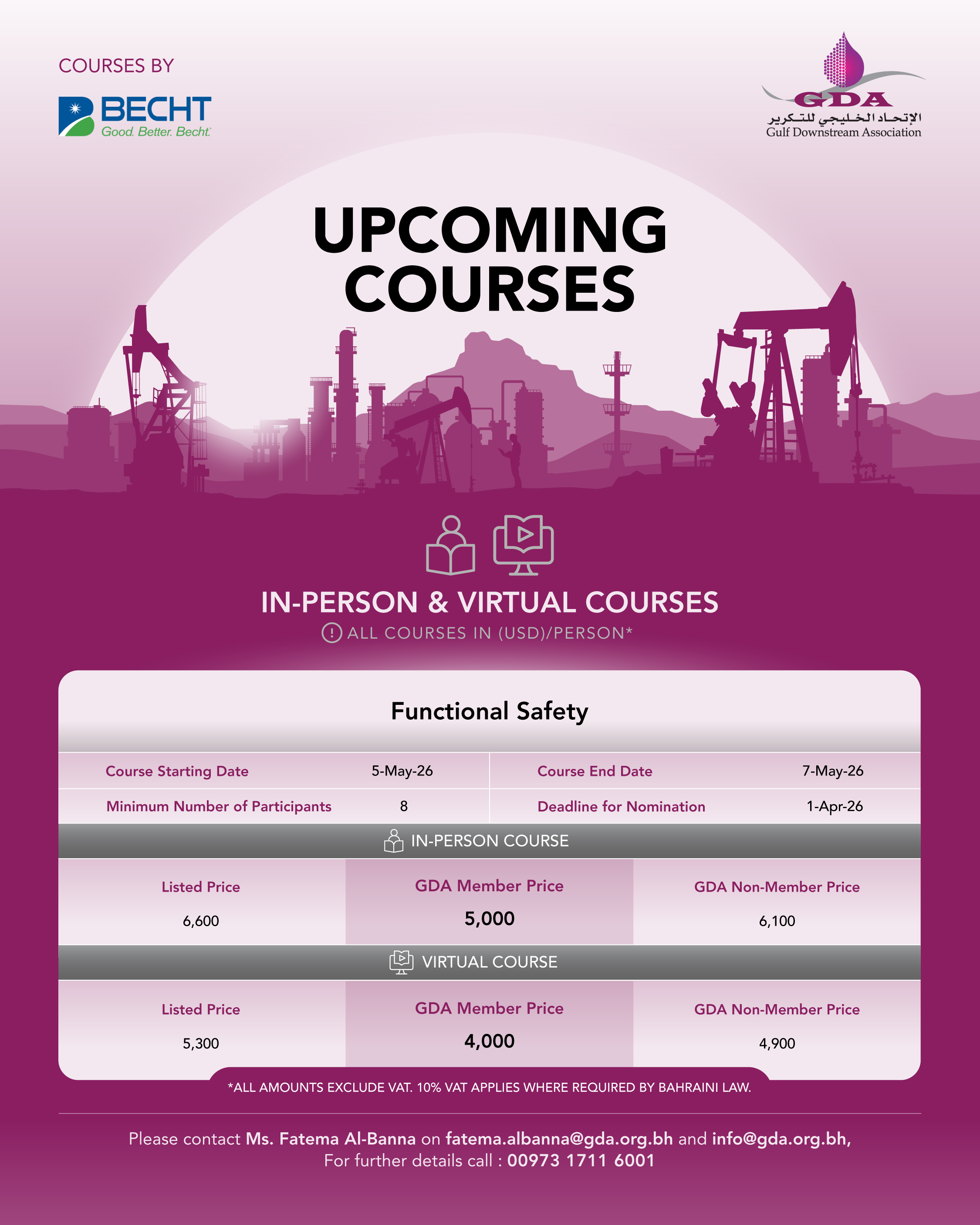

Fired Heaters Troubleshooting & Optimization

Course Summary:

This course provides a thorough understanding of combustion technology and the operation of fired heaters in refineries and petrochemical plants. Participants will learn the fundamentals of combustion, equipment optimization, and troubleshooting techniques to improve heater efficiency and safety. The course will cover the critical aspects of hardware, instrumentation, and process applications, enabling participants to enhance the thermal efficiency and operational performance of fired heaters.

Course Benefits:

Upon completion of this course, participants will:

§ Understand the basics of combustion and best practices for operation.

§ Learn about fired heater hardware and instrumentation.

§ Perform rough calculations to troubleshoot field problems.

§ Optimize the operation and thermal efficiency of fired equipment.

Course Contents:

1. Combustion Theory:

v Fundamentals of fuel combustion.

v Furnace efficiency calculations.

v Understanding flammability limits.

2. Burners:

v Types of burners and their operating characteristics.

v Techniques for burner optimization.

3. Atomization (for oil-fired systems):

v Types and characteristics of atomizers.

v Optimization of atomizers for efficient combustion.

4. Low NOx Burners:

v Formation of NOx and solids.

v Techniques for reducing NOx emissions and environmental impact.

5. Furnaces:

v Purpose, process applications, and layout of furnaces.

v Key factors in furnace efficient, heat transfer, and two-phase flow.

v Addressing issues like furnace tube overheating and coke formation.

6. Air Preheat:

v The impact of air preheat on furnace efficient.

v Types of air preheat systems and maintenance considerations.

7. Furnace Control and Safety:

v Control schemes for air/fuel ratios.

v Safeguarding mechanisms, including flame detection and low-pressure trips.

8. Furnace Draft:

v Understanding pressure profiles in natural and forced draft systems.

v Calculating actual draft levels in combustion systems.

9. Start-up and Operation:

v Burner maintenance, inspection, and normal operating controls. 10. Furnace Tube Decoking:

v Techniques for removing coke from furnace tubes, including shot blasting and steam-air decoking.

11. Refractory:

v Best practices for maintaining furnace refractory integrity and drying procedures.

12. Furnace Tube Failure:

v Identifying, preventing, and managing furnace tube failures.

13. On-Line Chemical Cleaning:

v Use of fuel and radiant cell additives to improve furnace performance.

14. Trial for Ignition Time:

v Critical safety parameters and calculation of safe time periods for furnace purge and ignition.

Target Audience:

This course is ideal for individuals involved in refinery and petrochemical plant operations, specifically those responsible for fired heaters. It is particularly useful for:

§ Plant and maintenance engineers

§ Process engineers

§ Control engineers

§ Operators and technicians responsible for furnace efficiency, safety, and maintenance Additionally, professionals involved in furnace design, troubleshooting, and emissions management will benefit from the comprehensive coverage of combustion and heater technologies.

Prerequisites:

There are no strict prerequisites for this course. However, a basic understanding of refinery operations and familiarity with combustion principles will enhance the learning experience. The course is designed to accommodate both beginners and experienced professionals seeking to improve their knowledge of fired heater operations.

Instructor:

Belal Hassoun, P. Eng. Belal Hassoun is a Senior Fired Equipment Engineer with over 23 years of experience in the oil and gas and petrochemical industries. Throughout his career, he has specialized in the design, commissioning, and optimization of fired heaters, offering extensive expertise in troubleshooting, emissions reduction, and operational efficiency. Belal has led critical projects, including start-ups, training programs, and fired equipment inspections, ensuring compliance with industry standards and improving profitability for refineries and petrochemical plants globally. His experience spans both operator and engineering roles, with notable leadership in both operational improvements and capital projects.